New Vessels Update | August Newsletter

Introduction

This newsletter brings you the latest on vessel progress, key milestones, and recent visits to Vietnam, as well as a first look at design concepts for the interiors. With momentum building and launch preparations now on the horizon, we are moving ever closer to delivering a modern, sustainable fleet for the islands.

Business of the year

We were proud to be named Business of the Year at the 2025 Maritime UK Awards in June.

This recognition came as we marked one year since the first steel was cut for our new vessels, Scillonian IV and Menawethan – a major milestone representing the biggest investment in the Isles of Scilly’s transport in a generation.

The award celebrated our commitment to innovation, advanced technology, and excellence in building these state-of-the-art vessels. It was a proud moment for everyone involved at the Steamship Group and reinforced our dedication to delivering a sustainable, modern fleet that will serve the community for decades to come.

Luke Parnell | Visit to Vietnam shipyard

In May we welcomed Luke Parnell as our new Technical Superintendent, playing a pivotal role in overseeing and managing the maintenance of our vessels.

Chief Executive Stuart Reid said:

“Luke’s familiarity with our current vessels and operations, as well as experience with new builds, will be a real asset for the future.”

Earlier this month, Luke visited Piriou’s shipyard in Vietnam to familiarise himself with Scillonian IV and Menawethan. He will return at the end of August for a two-week period, providing cover for Chris and Peter during their annual leave.

During this visit, Luke will oversee key stages of progress. On Scillonian IV, he expects to see the completion of welding installation and integrity testing of the starboard fin stabiliser, as well as the final inspection of Void 1 before it is sealed for the next five years. He will also check on the installation of the floating floor on Deck 2, which is on course to be completed during his time in the yard. The main gearbox preliminary alignment should also be finalised, with full alignment scheduled once the vessel is afloat.

On Menawethan, Luke will attend the final inspection of the propellers and tailshafts, while advanced systems testing continues. Both the compressed air system and the sewage vacuum system are due to be presented for inspection by Owners and Class. Inspections of the anchor chain locker and pallet lift are also planned. Externally, the final topcoat of hull paintwork should be completed during his stay.

Stuart Reid | Visit to Vietnam shipyard

“Seeing the vessels in Vietnam come to life since we started this project in 2019 is inspiring and a proud moment for the Company.”

Earlier this month, Stuart Reid travelled to Vietnam for an important stage in the vessel build. His visit included time at the Piriou shipyard to inspect progress on both vessels, as well as a stop at the furniture manufacturing factory to review materials and the quality of construction for the passenger lounges furniture and interior outfitting.

It was also a valuable opportunity to spend time with project managers Chris and Peter, who have been based in Vietnam for the past 14 months. Seeing first-hand the strong relationships they’ve built with the workforce was a highlight, and we’re proud of the professionalism and commitment they continue to bring to the project.

Since Stuart’s last visit, the transformation has been remarkable: hull units fully integrated, staircases and engines in place, windows being installed, and electrical teams laying kilometres of cabling each week.

Scillonian IV interior concepts

In this issue, we’re pleased to share a conceptual look into Scillonian IV, created by design specialists. These concepts help visualise the overall look and feel of the vessel’s interior as we reach a key stage in development, moving from initial ideas towards final designs, materials, and finishes. They illustrate the vision for passenger lounges, café areas, and other key spaces on board.

During his visit to the furniture manufacturing factory in Ho Chi Minh, Stuart Reid reviewed interior materials being prepared for fit-out and provided feedback on elements that were well received by the shipyard. The factory, renowned for superyacht outfitting, showcased the high-quality construction and materials being deployed for the vessel.

The discussions and feedback from this visit will guide the next stage of development, helping ensure the interiors achieve the right balance of comfort, style, and functionality for passengers.

Our next key milestones

Things have progressed at pace over in Vietnam since our last newsletter in June with exciting and key milestones coming up over the next few months.

Recent news bites

In case you missed it, here’s a recap of our updates since our last newsletter in June.

IPE visit for FATs

Megablocks 3 & 5

Scillonian’s main engines

France visit

Video updates

Megablocks 3 & 5

Construction of both new vessels is progressing using a unit construction method, where smaller blocks are integrated into larger megablocks before being assembled onto the hull. The video updates below showcase the erection of megablocks 03 and 05 onto the Scillonian IV hull, highlighting the specific sections of the vessel they form.

Podcast – coming soon

A Q&A with Arjen Barendse, Sales Manager at Hull Vane.

In this episode, our Group Marketing and Communications Manager, Sharon Sandercock, sits down with Arjen Barendse from Hull Vane, to discuss the Hull Vane technology being installed on Scillonian IV, and what service improvements this will have for both our passengers and operations.

Menawethan Walkthrough

As the Menawethan build progresses, project manager Chris Lingham walks us through the various areas of the vessel showing how the vessel is taking shape over in Vietnam.

Workforce Spotlight

We are continually impressed with the highly skilled and dedicated workforce of around 285 people, including 70 painters (20 on night shift) working together to build our new vessels. The team is at the heart of the Scillonian IV and Menawethan builds – from steel hull construction to electrical cabling and interior outfitting, their professionalism and precision are driving rapid progress. Staff work in challenging conditions, including high heat, humidity, noise and dust, necessitating the use of full PPE as they work on and around the vessels, be it on scaffolding or crawling through tanks, all while maintaining strict health and safety standards.

Chief Executive Stuart Reid, who visited in August, praised the workforce’s skill and commitment. “The volume and quality of work completed in just 14 months is exceptional,” he said. Project managers Chris Lingham and Peter Broad, living in Vietnam, coordinate daily with the team, ensuring smooth progress and close attention to detail. Their leadership, combined with the workforce’s dedication, is key to delivering vessels that will set a new standard for service to the Scilly community.

Scillonian IV | Build Update

Next Steps

Over the coming months, Chris and Peter will continue to lead detailed design reviews and monitor progress closely with the shipyard. They will also review outstanding action items and cost options with Piriou, ensuring that every element meets our high standards. Preparations are underway for the vessels to enter service, including crewing, certification, and familiarisation, while continued inspections will ensure all work is completed to specification.

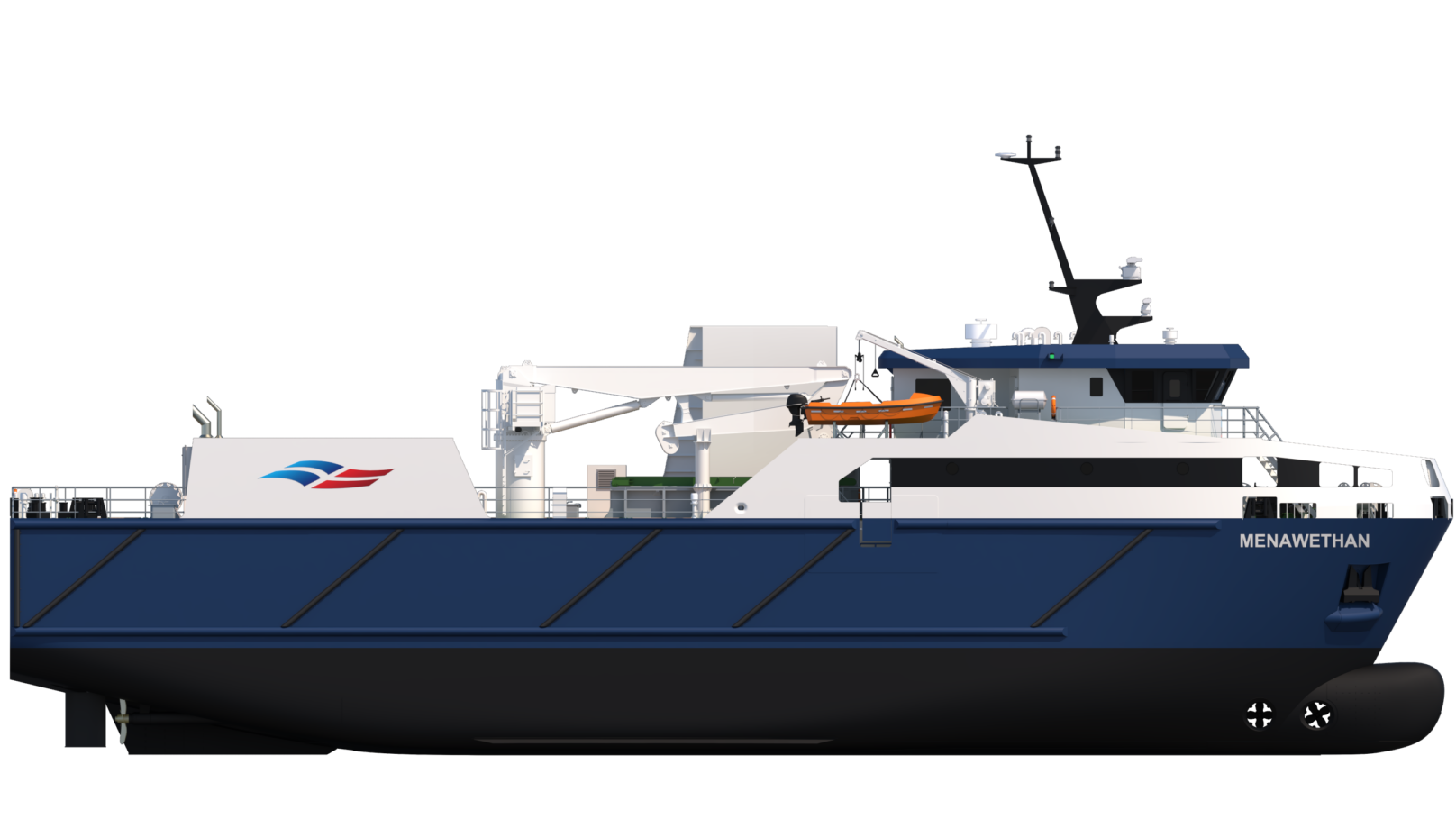

Menawethan | Build Update

Hull and Structural Work

Steel construction of Menawethan is complete, with all vessel sections fully integrated together including the main mast. Blasting and first coat painting is complete across all internal and external areas, including the hull, bulwark, top deck, hatch coamings, cargo holds and tanks. Installation of inner stern tubes is complete, with tailshafts and propellers installed, and rudder stocks and rudders mounted. Work is now progressing with the installation of the Wills-Ridley steering gear.

Machinery and Technical Spaces

Significant progress continues in the machinery spaces, with the installation of pumps, valves, compressors, fans, and the exhaust gas treatment plant. Several pipe systems have now been completed and pressure tested, including fuel transfer, fuel cargo, bilge, lube oil, ballast, and fire main systems. Installation of HVAC, refrigeration, and sewage plant continues, alongside other mechanical and technical outfitting.

Accommodation and Interiors

Outfitting of crew accommodation and passenger lounges is progressing well. Thermal, fire boundary, and acoustic insulation for bulkheads and deckheads in accommodation and technical spaces is approaching completion, ensuring compliance with statutory regulations and providing a comfortable environment for our crew and passengers. The installation of bulkhead panels in the crew and passenger accommodation is around 75% complete. En-suite units have been installed for the crew cabins, with plumbing and vacuum piping installation progressing steadily, ensuring that all accommodation spaces are moving toward completion.

Electrical and Systems Installation

Many of the electrical distribution boards and starter cabinets have now been installed and a lot of work has been done to install electric cabling throughout the vessel.

Next Steps

Continued outfitting work to fully mount machinery and route piping and electric cabling. Complete painting of internal areas and tanks. The underwater and topsides of the hull have already received the first coat of paint, the next step being to apply further coats of paint, totalling 4 coats for the topsides and 5 coats for the underwater areas.

Continued outfitting work in the accommodation areas to install ceiling panels, ventilation outlets and flooring. And in the wheelhouse next step is to install the consoles that house the manoeuvring, navigation and control systems for the vessel.

Our teams continue to monitor progress closely to ensure all work meets high standards, as the build of the vessel moves closer to launching and the start of commissioning.

Keep up to date

Keep up to date on the progress of our vessel replacement project across our social media channels and website, where you will find the latest newsletters, podcasts, photos, films and more.

Isles of Scilly Steamship Group – Linked In