New Vessels Update | June Newsletter

Introduction

Welcome to the 13th edition of our New Vessels newsletter – a special update marking one year since construction began on Scillonian IV and Menawethan.

It’s now twelve months since the first steel was cut in Vietnam, marking the launch point for what has become a remarkable shipbuilding journey. Since then, we’ve seen the two vessels really begin to take shape – now, nearly fully integrated vessels, with staircases, pipework, electrical systems, gearboxes, engines and more already in place.

Since our last update two months ago, progress has continued at pace. With so much to share, we’re introducing our new-look newsletter to help you follow each step of the project more clearly.

In this edition, we’re looking ahead to the next major milestones – but first, we take a look back at the timeline that’s shaped an extraordinary first year of construction .

A year in construction – key milestones

What’s happening next?

Things are constantly progressing at pace over in Vietnam and over the next few months, members of our senior management and marine operations teams will be heading out as the build progresses.

Recent news bites

In case you missed it, here’s a recap of our updates since our last newsletter in April.

Inspecting electrical distribution cabinets and consoles

Factory Acceptance Tests (FATs) of key electrical systems

Testing hydraulic power systems – designed and built by Cornwall based Armada Engineering

The essential auxiliary equipment hydraulic power systems, designed and built in Falmouth, Cornwall by Armada Engineering, underwent successful factory testing ahead of shipping to Vietnam and installation on board Scillonian IV and Menawethan.

These systems will power key machinery like the tunnel thrusters, windlass, cargo hold hatch, cargo crane, cargo pallet hoist and side door on Menawthan and the windlass and gangway davits on Scillonian. Our project manager, Chris Lingham, joined representatives from Lloyd’s Register, Piriou and ISSG to witness the Factory Acceptance Tests (FATs) and confirm performance to specification.

Video updates

Build update

Starboard main engine and gear box installation on Scillonian IV with Peter Broad (site manager)

Podcast

Stuart Reid (ISSG CEO) and Jean-Baptiste (Piriou Shipyard)

In May, we sat down with Stuart Reid and Jean-Baptiste from Piriou Shipyard to discuss the partnership behind this landmark project and how we are working together to create the new vessels tailored to serve the unique needs of the Isles of Scilly community.

Walkthrough

As the Scillonian IV build progresses, project manager Chris Lingham walks us through the various areas of the vessel showing how the vessel is taking shape over in Vietnam.

Build update | Scillonian IV

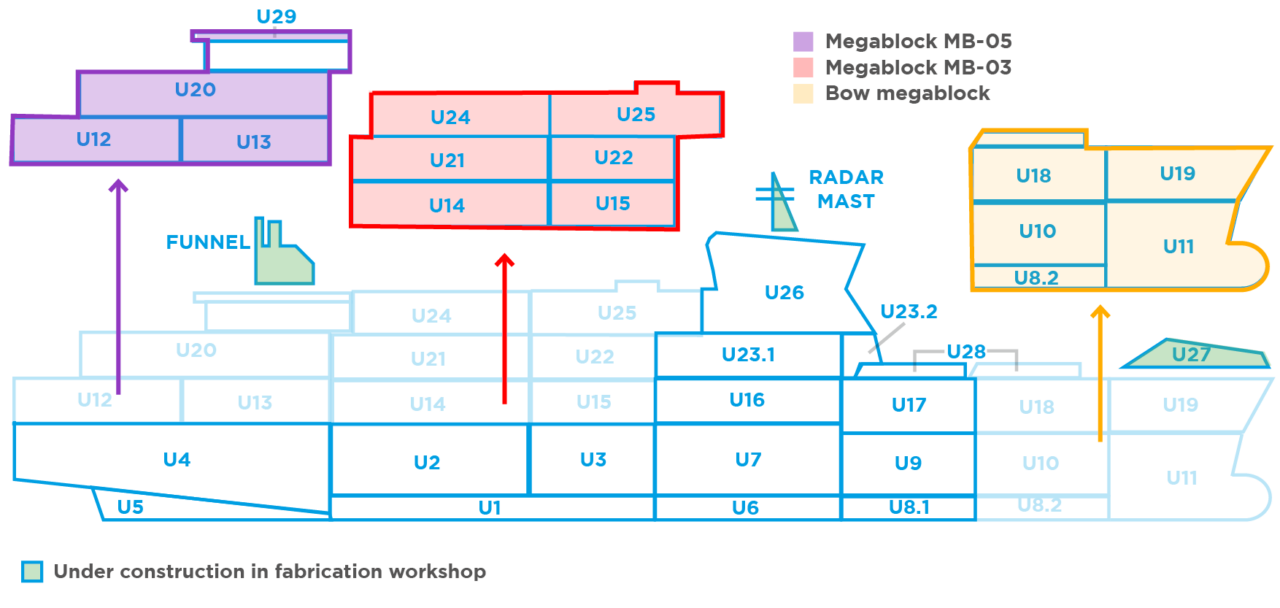

The steel and aluminium structure of Scillonian IV is now over 95% complete, with all the main hull units fabricated. The cargo hatches, bow bulwark, funnels and radar mast, are all currently under construction in the fabrication workshops.

While the main hull continues to take shape in the building dock, three large mega blocks – MB03, MB05, and the bow megablock are being constructed on the dockside. These blocks, made up of multiple units, have been moved to the dockside to undergo outfitting including piping, ventilation, cable trays, blasting and painting.

MB03 and MB05 will be integrated with the main hull after the installation of the major components of machinery into the engine room. This is made possible via a ‘soft patch’ – a removable section of deck above the machinery space that allows equipment to be craned into place and welded shut after installation.

So far, the following equipment has been successfully installed:

- Main engines and gearboxes

- Intermediate tailshafts

- Venitlation fans and trunking

- All three generator sets

- Both Selective Catalytic Reduction (SCR) exhaust treatment units

- Sewage treatment and vacuum toilet systems

- Refrigeration units for cold storage

- Air conditioning system

- Domestic hot water tanks (calorifiers) and air receivers

Mounting and alignment of these systems is ongoing.

At the bow, mega block integration is progressing steadily. This block is also being outfitted on the dockside and will be blasted and painted before final integration – scheduled to happen after Menawethan is launched in the autumn, freeing space in the dock.

Substantial progress continues with the manufacture and installation of pipework, cable trays, structural penetrations, and ventilation ducts.

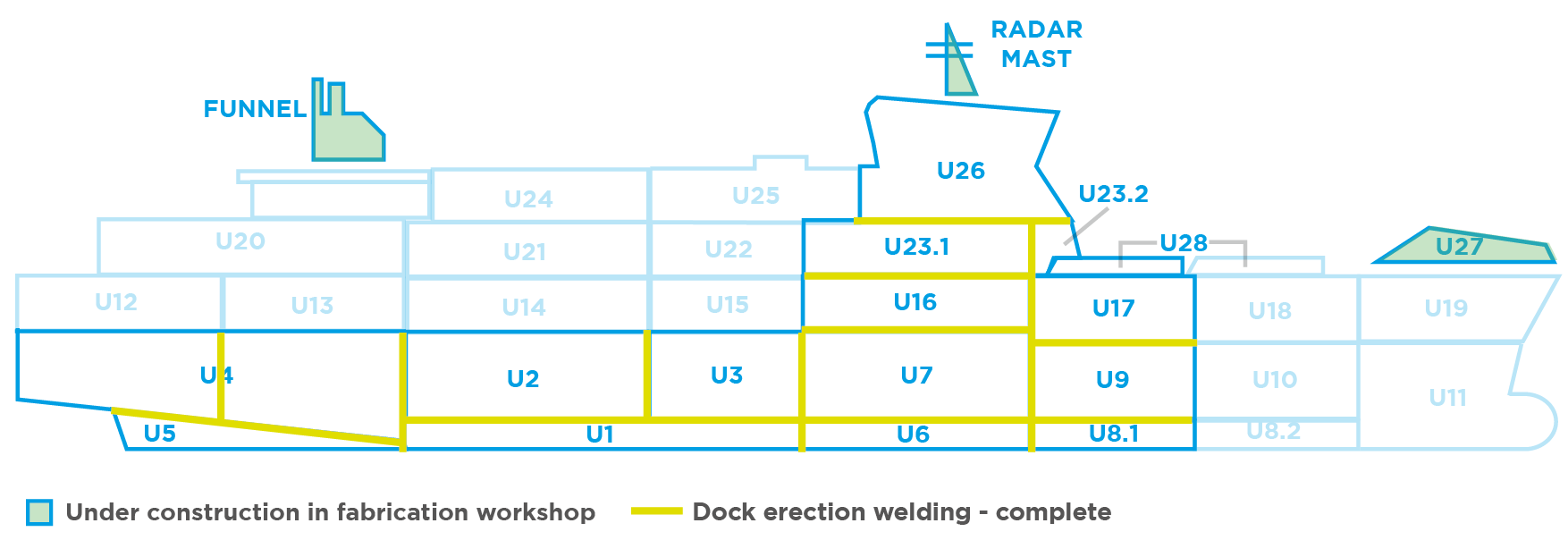

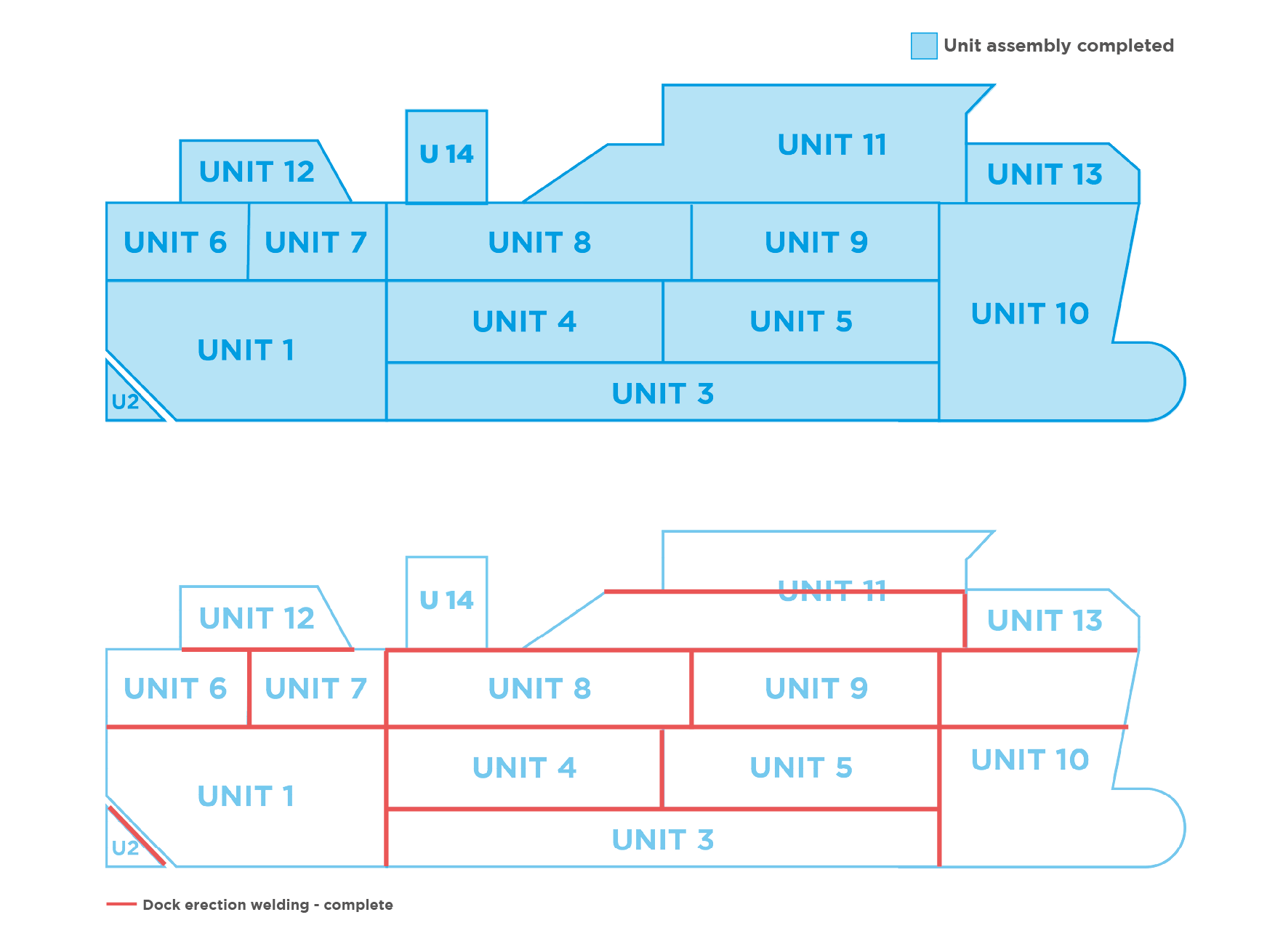

This illustration below shows where dock erection welding has been completed. Each of these mega blocks is fully integrated with all of their individual units.

Build update | Menawethan

Structural Progress

The steel structure of the vessel is now fully complete, with all units successfully integrated, including the side door for the pallet hoist.

The pallet hoist itself has been erected and inspected by the manufacturer’s service engineer, with final welding work now underway to secure it in place.

This illustration below shows where dock erection welding has been completed.

Keep up to date

Keep up to date on the progress of our vessel replacement project across our social media channels and website, where you will find the latest newsletters, podcasts, photos, films and more.

Isles of Scilly Steamship Group – Linked In